Thoughtfully designed products

that minimise the environmental impact of maritime operations and extend the lifetime of a vessel

Class Societies

Our Products

Clean Marine technologies can be implemented at various phases of the voyage lifecycle to improve operational efficiency, reduce fuel consumption, and capture harmful emissions.

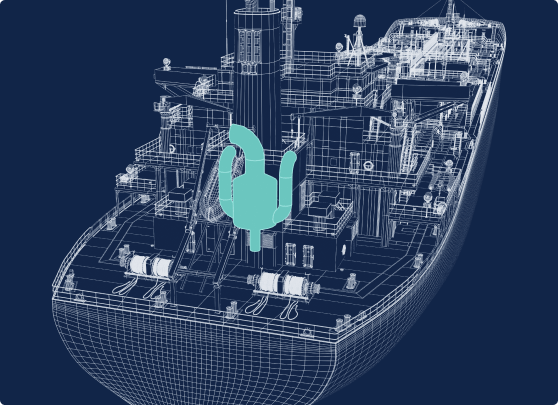

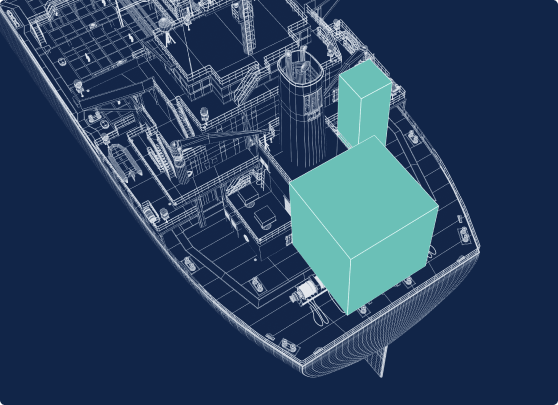

Exhaust Gas Cleaning System

Our scrubber features a robust U-type design which has been certified by leading Class Societies to reduce sulphur emissions to below 0.1%.

VIEW PRODUCT

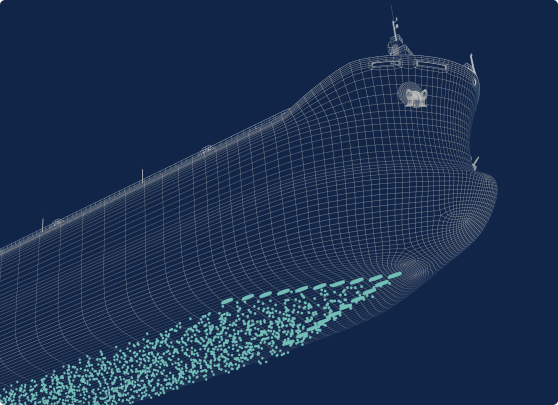

Air Lubrication System

Combining proprietary design and engineering with well-established air lubrication principles to deliver a substantial reduction for all ship designs.

VIEW PRODUCTIn Development

Our team of engineers are constantly innovating to tackle the environmental and operational challenges of the modern world.

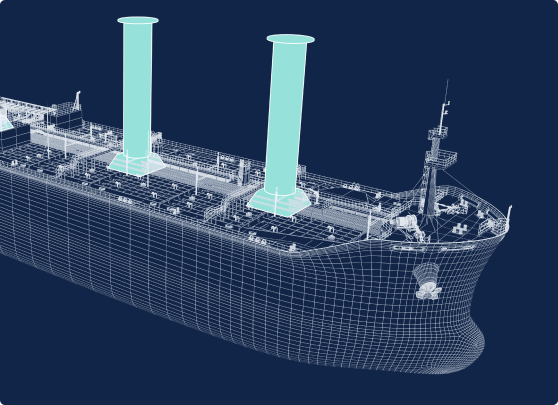

Rotor Sail

Utilising wind propulsion technology that has existed for over a hundred years, we have adapted and refined the design to meet the needs of today.

ENQUIRE NOW

Carbon Capture

The final step in a holistic decarbonisation strategy, carbon capture systems remove harmful emissions before they reach the atmosphere.

ENQUIRE NOWSupporting you all the way

Benefit from Clean Marine expertise at every step, with our thorough training and after sales services.